Energy efficiency has become one of the main objectives of modern industry. You know that reducing consumption not only means saving costs, but also complying with environmental regulations and maintaining competitiveness in an increasingly demanding market. In this scenario, valves and instrumentation play a fundamental role by enabling more precise control of resources on board ships and in industrial facilities.

Fuel consumption optimization

Fuel is one of the biggest expenses in any maritime operation. You will see that a poorly calibrated valve or an inaccurate meter can lead to significant losses. Thanks to modern instrumentation systems, it is now possible to accurately measure fuel flow and automatically adjust consumption based on the ship’s load and route.

This not only increases efficiency, but also reduces pollutant emissions, aligning with international sustainability goals.

Real-time temperature and pressure control

Maintaining stability in steam, refrigeration, and boiler systems is essential to avoid energy waste. Those of you who work with these installations know that advanced instrumentation allows for continuous pressure and temperature control, adjusting parameters without the need to shut down operations.

These automatic adjustments ensure more efficient performance and extend the life of the equipment, reducing the need for corrective interventions.

Automation in resource management

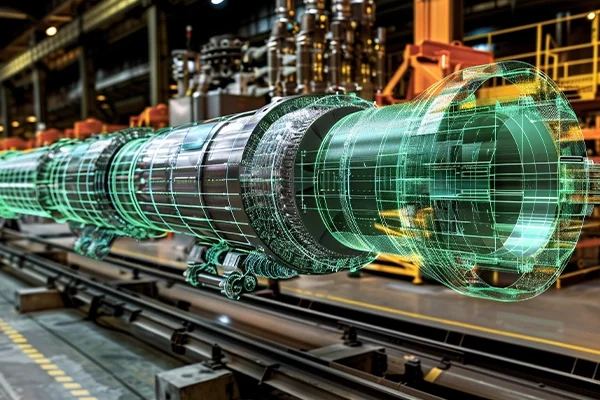

The incorporation of automatic valves and smart sensors is transforming the way naval and industrial systems are managed. You will see that these technologies allow fluid flow to be regulated according to actual demand, preventing overloads and leaks that previously went unnoticed.

Automation also frees crews from repetitive tasks, allowing them to focus on strategic tasks and increasing operational safety.

Impact on environmental sustainability

One of the great benefits of modern valves and instrumentation is their ability to reduce carbon footprints. By preventing leaks, optimizing flow rates, and ensuring more rational energy consumption, they contribute directly to reducing greenhouse gas emissions.

You will see how more and more shipowners and industrial companies are committed to updating their control systems as part of their environmental and corporate responsibility strategy.

Return on investment and competitiveness

Investing in state-of-the-art valves and measuring equipment may seem costly at first, but the return is clear. Reduced consumption, fewer unexpected shutdowns, and greater operational safety translate into savings in the medium and long term.

Those of you who manage operations know that competitiveness depends not only on offering a service, but on doing so efficiently. Modern instrumentation has become a decisive factor in standing out in a global market.

Conclusion

Energy efficiency is no longer an optional goal, it is a requirement. And valves and instrumentation are essential allies in achieving it. Those of you who are involved in day-to-day naval and industrial operations know that every valve and every sensor counts.

Investing in innovation and automation not only improves immediate results, it also ensures a more sustainable and competitive future in an industry that is constantly evolving.