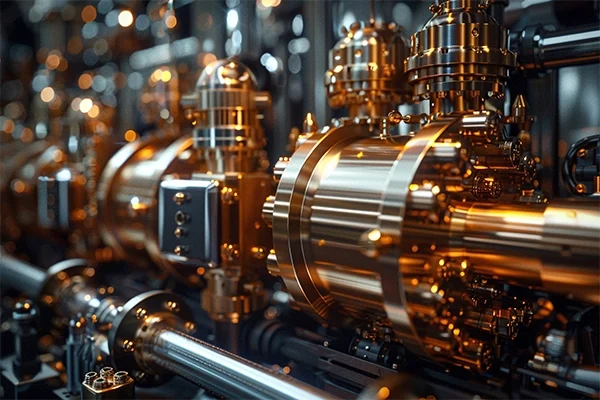

In any industrial facility or vessel, efficiency depends on precision. You know this well: a hydraulic or steam system cannot function without reliable valves, nor can a power plant control its performance without accurate measuring instruments. Valves and instrumentation are therefore the silent heart of industry and the naval sector, ensuring safety, continuity, and control in every process.

The importance of valves in demanding environments

Valves are not just simple connecting pieces. You will see that they act as essential regulators of the flow of liquids, gases, and vapors in extreme conditions. In the naval sector, where ships operate with pressure, fuel, and cooling systems, having certified valves makes the difference between efficiency and risk.

There are different types of valves—gate, ball, butterfly, and check valves—that are adapted to specific needs. Those of you who work in maintenance know that the right choice ensures the safety of the crew and extends the life of the equipment.

Instrumentation: measuring to control

Without data, there is no control. Pressure gauges, thermometers, flow meters, and pressure transmitters are indispensable tools for knowing the status of a facility or ship in real time.

In the naval sector, instrumentation allows you to monitor boiler pressure, engine temperature, and fuel flow. This information is vital for anticipating problems, avoiding unexpected shutdowns, and optimizing resource consumption.

Innovation in valves and instrumentation

Technological innovation has also reached this field. Today, there are smart valves that integrate sensors to send data in real time, facilitating much more effective predictive maintenance.

Likewise, digital instrumentation allows you to have remote access to information from a central panel, streamlining decision-making and improving safety. The combination of IoT (Internet of Things) and digital control systems is revolutionizing the way equipment is managed on ships and in industries.

Maintenance and reliability as a priority

A failure in a valve or pressure gauge can have serious consequences. That is why preventive maintenance is essential. You know that regularly checking seals, calibrating instruments, and replacing worn parts ensures continuity of operations and avoids unnecessary costs.

In addition, working with trusted suppliers gives you the assurance that your equipment complies with the most demanding international standards, which is essential in both industrial and naval environments.

Sustainability and energy efficiency

Modern valves and instrumentation also contribute to sustainability. You will see that precise control of fuel flow and energy consumption reduces emissions and makes better use of resources.

On ships and in factories, this level of efficiency not only improves profitability, but also helps to comply with increasingly stringent environmental regulations.

Conclusion

Valves and instrumentation are much more than technical parts: they are the nervous system of industry and the naval sector. Those of you who work with them know that every valve and every pressure gauge has a direct impact on the safety, efficiency, and sustainability of any operation.

Investing in innovation, maintenance, and continuous training means investing in a safer and more competitive future. Because in a world where every detail counts, precision always makes the difference.